Sanofi Launches Digital Drug Manufacturing Facility

The facility uses leading-edge tech to improve the commercialization of novel drugs.

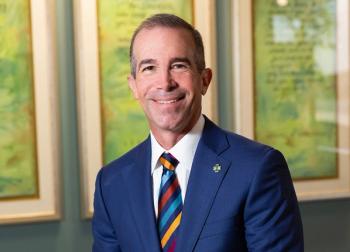

Photo/Thumb have been modified. Courtesy of

Global pharmaceutical giant Sanofi today

Located in Framingham, Massachusetts, the facility features leading-edge technology that connects the production process with research and development to improve the commercialization of novel medicines for patients.

“With increasing advances in medical science and innovation, complex medicines are set to become even more important in improving people’s health worldwide,” Sanofi said in an

Sanofi has been building the facility, which cost nearly $5.2 billion, for the last five years.

The facility features new connected and intelligent equipment, process technology and solutions to augment operators.

“It will allow us to deploy advanced data analytics solutions to further improve the quality, yields and reliability of our facilities and optimize our inventories and logistic flow,” Sanofi said.

Production and data will be documented in real time, resulting in a paperless manufacturing solution with electronic batch records, review and right time release and real-time process control.

Sensors will share information about the drugs and create more than 3 billion data points from 5,000 parameters for one standard batch. When the data are analyzed, employees can access the findings to better understand the complexities of the process.

Sanofi’s digital transformation of its manufacturing network is a major aspect of its goal to leverage better use of data to optimize manufacturing processes. Digitization could help the company increase efficiencies and improv the agility needed to respond to ever-changing patient needs. What’s more, going digital will speed up the commercialization of new medicines from Sanofi’s research and development pipeline.

“Our Framingham facility leads the way in delivering the next generation of biologics manufacturing, leveraging intensified, continuous processing in a fully integrated digitally powered facility,” said Philippe Luscan, executive vice president of global industrial affairs at Sanofi. “This opening demonstrates we are at the leading edge of innovation and manufacturing excellence, helping us to shape the future of both our company and the industry.”

Get the best insights in digital health

Related